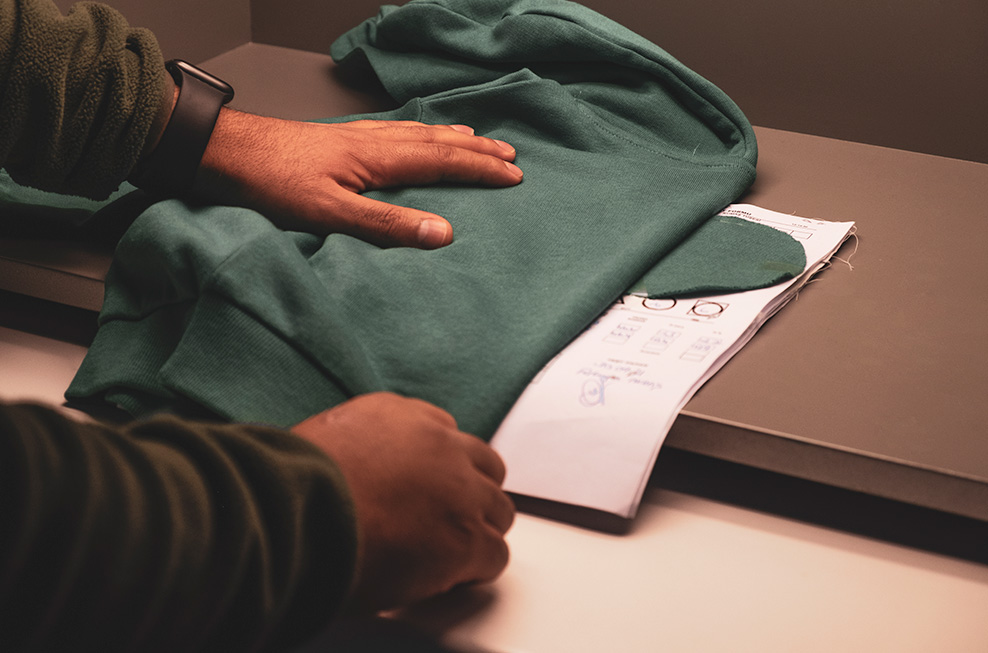

Quality Control

Quality is one of Sumoteks' top priorities throughout all production processes. Products are constantly monitored through intermediate checks and undergo multi-stage quality control processes, including post-sewing and pre-shipment. During final inspections, products are evaluated according to customer instructions and AQL standards.

The quality control process isn't limited to identifying defects; it also encompasses providing feedback that will improve production quality. Sumoteks' quality control team meticulously tests measurements, stitching, appearance, accessories, and functionality using checklists specific to each product group. The digital quality monitoring system records data at every stage, allowing for performance analysis and identifying areas for improvement. Furthermore, final inspections prior to shipment ensure that each product complies 100% with customer expectations and technical specifications. Sumoteks views quality not as a single outcome, but as a responsibility encompassing the entire process, and acts accordingly.

+90 (262) 422 24 11

+90 (262) 422 24 12

+90 (533) 136 45 70

© 2025 Sumoteks - All Rights Reserved. Designed by MonoPenta C.B.