Production and Supply

Our Facility Infrastructure

Sumoteks has a semi-integrated production facility with a 12,021 square meter indoor area to maximize production efficiency. Located in Gölcük/Kocaeli, this facility manages cutting, printing, sewing, ironing, quality control, and packaging operations under one roof. This ensures the highest level of quality control, time management, and resource optimization at every stage of production.

Production Capacity

Our current production capacity is 550,000 units per month. Thanks to our strong solution partnerships and our domestic and international production networks, we have the flexibility to increase this capacity by 1.5 million units depending on demand.

Cutting

Printing

Sewing

Sumoteks' sewing lines are staffed by teams specializing in basic, medium, and complex product groups. During this phase of production, attention is focused on details that enhance both standard compliance and user comfort. This stage ensures that products are aesthetically pleasing, durable, and functional.

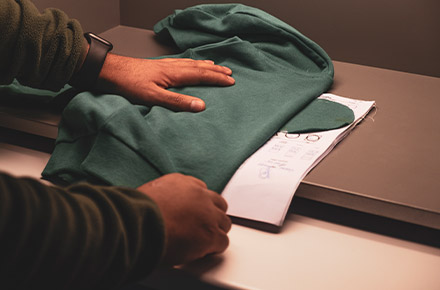

Iron Packaging

After the finished products undergo quality control, they undergo a professional ironing process. They are then folded, labeled, and packaged according to instructions, ready for shipment. During this process, the product's presentation quality is also meticulously evaluated.

Quality Control

Quality is one of Sumoteks' top priorities throughout all production processes. Products are constantly monitored through intermediate checks and undergo multi-stage quality control processes, including post-sewing and pre-shipment. During final inspections, products are evaluated according to customer instructions and AQL standards.

Sumoteks' quality control team not only detects errors but also supports a culture of continuous improvement by providing quality-enhancing feedback.

Production Tracking System

Thanks to the digital monitoring system used in our production line, time losses, efficiency, individual performance and quality rates are measured, and continuous improvement is aimed through analysis and reporting.

Our Facility Infrastructure 01

Our Facility Infrastructure 01

Sumoteks has a semi-integrated production facility with a 12,021 square meter indoor area to maximize production efficiency. Located in Gölcük/Kocaeli, this facility manages cutting, printing, sewing, ironing, quality control, and packaging operations under one roof. This ensures the highest level of quality control, time management, and resource optimization at every stage of production.

Production Capacity 02

Production Capacity 02

Our current production capacity is 550,000 units per month. Thanks to our strong solution partnerships and our domestic and international production networks, we have the flexibility to increase this capacity by 1.5 million units depending on demand.

Our Supply Chain Management 03

Our Supply Chain Management 03

At Sumoteks, we approach our supply chain not merely as a logistics network, but as a strategic structure that generates value. From raw material procurement to final product delivery, all processes are managed in a transparent and verifiable manner. The origin, content, and certifications of fabrics, auxiliary materials, and accessories used in the production process are recorded, providing our customers with full traceability. Our supply chain management is based on the principles of efficiency, quality, compliance, and speed. We offer our customers not only products but also a sourcing experience that minimizes risks, instills confidence, and supports sustainability.

As Sumoteks, we have been producing children and baby clothes for global brands since 1998. By prioritizing quality, sustainability and safety, we carefully realize the products that the children of the world love to wear.

+90 (262) 422 24 11

+90 (262) 422 24 12

+90 (533) 136 45 70

© 2025 Sumoteks - All Rights Reserved. Designed by MonoPenta C.B.